Facilities overview

Quality Control Policy

The Saudi Land Factory for Cement Products depends on the American specifications ASTM and the Saudi specifications SASO in the manufacture of concrete products that it produces: ASTM C76 . Open Excavation Reinforced Concrete Pipes ASTM C478 . Reinforced Concrete Septic’s And since the main purpose of establishing the factory was to produce high quality products according to specific specifications and standards, the technical management of the factory divided the quality control

into three stages:

Pre-production stage

It is the design of the concrete mixture according to the American specifications, the work of experimental concrete mixtures, taking samples and testing them to reach the best results and to ensure that the products conform to the design and make the necessary adjustment in the event of a change in the supplier of raw materials. The Quality Department also follows up, monitors and scrutinizes the dimensions of the reinforcing steel before casting the products. It also checks and tests the raw materials according to the following specifications. Specification Raw material ASTM C94 Water ASTM C33 Gravel and Sand ASTM C150 Cement ASTM C497 Rebar ASTM D412 Bushings ASTM C494 Chemical Additives

Production stage

The production process is followed up and monitored, step by step, to correct the simple notes, exclude defective products and isolate them from the product, if any, as well as take daily samples (cubes - cylinders) to ensure that the products conform to the design and make the necessary adjustment in case of changing the supplier, and follow up on the finishing of products and obtaining higher quality of products

Post-production stage

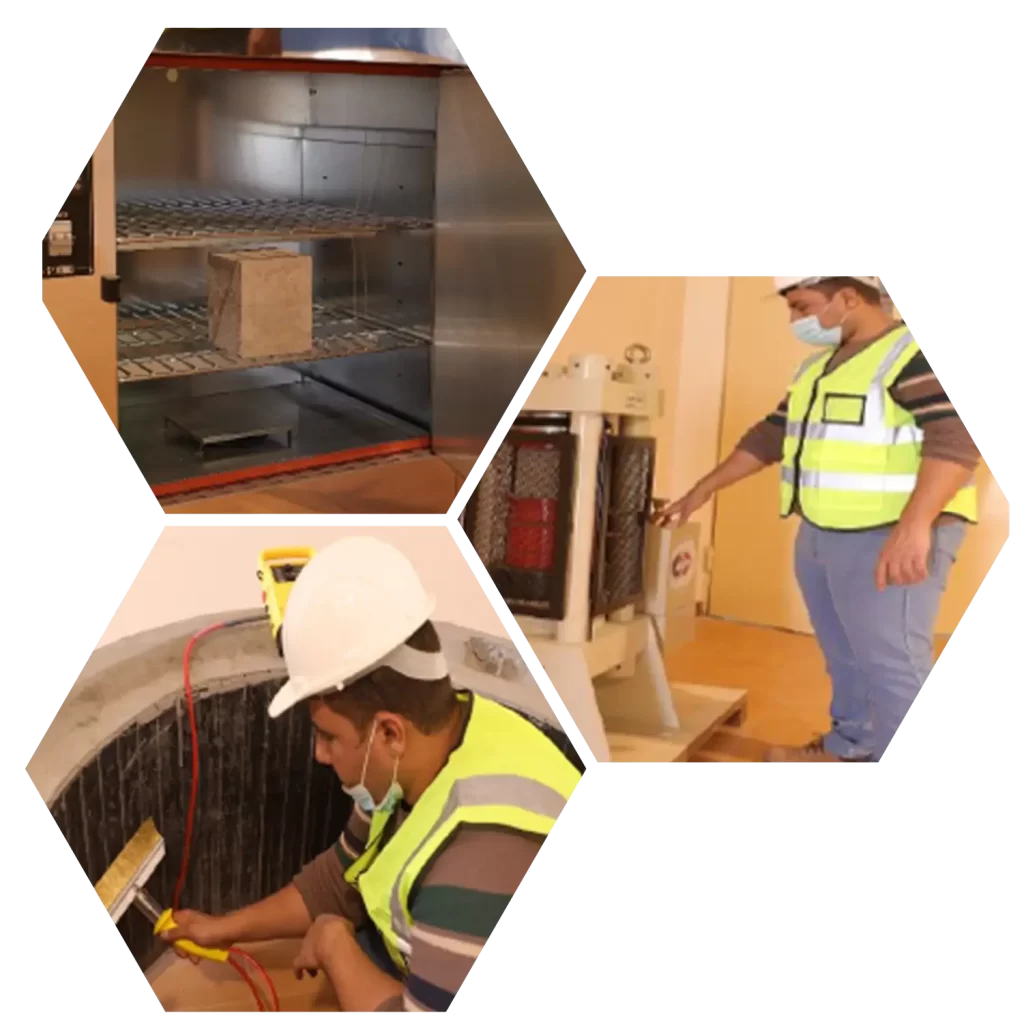

Cubes and cylinders are crushed to ensure that the products conform to the specifications. We also take random samples of the product and perform a crack and fracture test and an absorption test according to the approved specifications. The surfaces are also monitored to ensure that they are free of any dents, bulges or protrusions while ensuring that they are level and free of cracks or any apparent defects. Measurement of head and tail dimensions, internal diameter, wall thickness, length, straightness check, tensile testing of bushings and weld quality. The quality department is also responsible for product numbering, examination and testing of internal and external insulation of products until they are loaded onto the car for transportation to the site.

laboratory

The factory has a full laboratory that containsall the devices and equipment necessary totest materials and concrete to follow up and control quality operations. -Compression test machine -Sample oven -Sieve analysis -Spark tester to test liner -Dimensional measuring devices -sampling cubes and cylinders -Vibrator table to blood samples well -Digital balance Concrete mixer 60 Liter is used in the design

Central concrete batching plant Batch plant

production capacity: 45000 units/year The concrete mixture is prepared for pipes and manholes by means of a modern-made central mixer that operates with an automatic system to control the weights of all components of the concrete mixture (gravel - sand - cement - water - chemicals) to obtain a mixture that is completely identical to the design mixture. It also contains a tower to cool the water used with automatic control to ensure Controlling the temperature of the mixture before pouring with the possibility of saving and printing any concrete mixture that was produced on the date and timing of its implementation. Fly bucket) according to the production plan approved in the factory